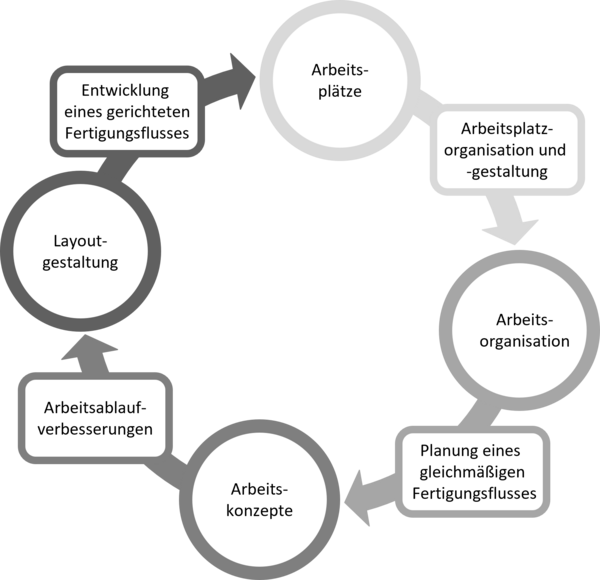

T&O Industrial Excellence guides you to your optimized real image in 8 steps. The services differ between ideal development (steps 1 to 4, without reference ot buildings and/or land) and real development (steps 5 to 8, with reference to buildings and/or land), which are applied depending on requirements.

Ideal Image Development

without reference to buildings and/or land

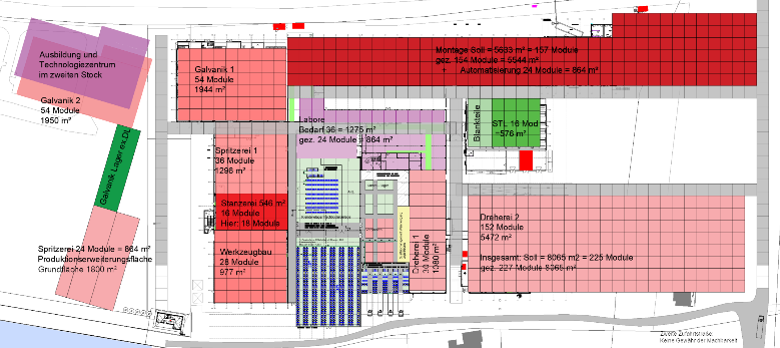

The segmentation aims to combine the cost and productivity advantages of flow production with the high flexibility of job shop production.

The manufacturing process is divided into several autonomous functional groups or manufacturing segments. In such a segment, several steps of the production process are reflected.

The goal is to achieve the same cycle times for workplaces and to be able to establish them in the production flow without buffer storage.

It is defined through the work instructions which work contents are assigned to the individual workplaces.

Each workplace is set up according to the process steps to be performed. The process steps at the workplaces then determine the micro-material flow and the workplace layout.

Our proven analyses of material handling

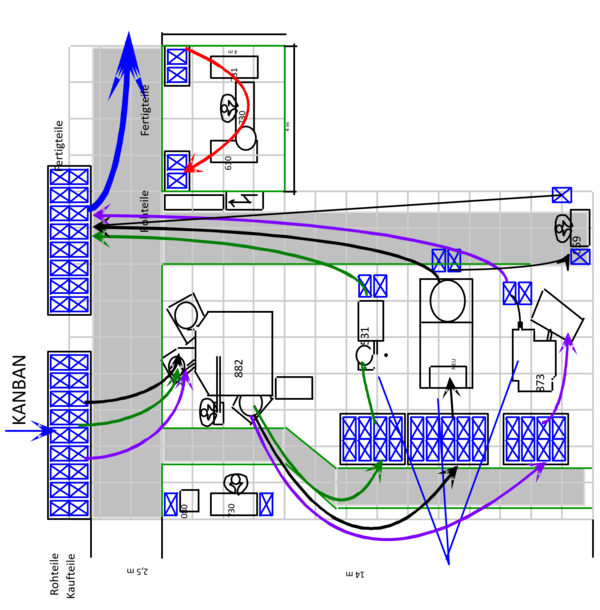

Handling analyses help to analyze and depict how often material is "touched" or moved. The goal of layout planning must be to move the material as little as possible and to store it in buffer storage. The handling analysis supports or complements the value stream analyses of the material flows.

The Arrangement of Workstations and Buffers Follows Our Fundamental Understanding

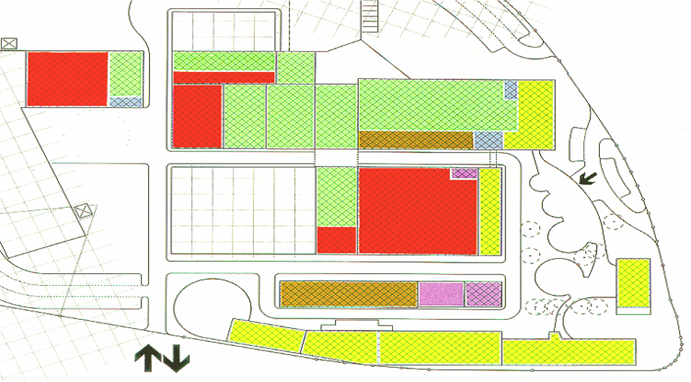

Goal Orientation, Success Positions and Core Competencies, High Depth of Manufacturing, Reorientation Towards Sales Control, Reduction of Complexity, and Building Flexible Process Organizations Shape the Areas. Process-oriented Manufacturing Areas with Complete Processing as well as Transparent and Manageable Macro Material Flows, Decoupling of Human and Machine Capacity.

Production Design and Material Flow Significantly Determine the Structure. The Arrangement of Workstations is Made Considering the Manufacturing and Material Flow. The Right Arrangement of Workstations in the Layout Favors the Reduction of Inventories (Buffers). Necessary Material Buffers Can Be Sensibly Defined.

Visual Management

We Consider Marking and Signage as Part of Visual Management.

Markings are Absolutely Necessary for Optimal Workflows and Additionally Support Keeping Production Sites Neat and Tidy. Floor Markings Serve to Visualize Storage Areas or to Define Boundaries of Areas. Storage Areas Are Not Only to Be Used for Placing Parts but Should Also Support the Factory Structure as Self-regulating Part Places.

These Are Essential Elements of a Comprehensive Visual Management.