At agiplan and the T&O Group, our experts combine decades of experience with innovative thinking to deliver logistics planning that not only meets your current needs but is also ready for future demands. We understand that effective logistics planning does more than just reduce costs — it enhances flexibility and strengthens your competitive position. We handle the planning for you, from site layouts and processes to the detailed simulation of individual workflows.

A site master plan lays the foundation for long-term business success.

Our approach goes beyond traditional, iterative concept development. Instead, we begin by creating an abstract ideal scenario, free from building constraints, to determine your company’s actual requirements in terms of space, functions, processes, and organizational structure.

Based on this, we then develop concept variants grounded in real-world conditions – such as existing buildings, property boundaries, or other planning constraints. These options are evaluated both qualitatively and quantitatively (including financial feasibility), allowing us to define a forward-looking target image. From this, we derive a detailed master plan, which includes a phased implementation roadmap over a defined timeframe.

Our goal is to position your site for the future: functional, logistics-focused, and flexible.

WMS, WCS, WES, ERP – which systems are the best fit for your logistics processes? What systems do you already have in place, and are extensions or integrations possible?

The success and efficiency of your operational processes depend heavily on your IT infrastructure – and that infrastructure varies in complexity depending on your individual requirements.

When designing processes and systems, we consider a wide range of factors including warehouse strategy, warehouse organization, logistics and control processes, production planning, order types, batch tracking, picking methods, and more.

We define and design processes based on the required capabilities and economic feasibility, and map them into a suitable IT structure. This forms the basis for a gap analysis, which leads to the creation of a detailed requirements specification for your logistics IT system.

These requirements form the foundation for your tender documents.

Our services include the detailed planning of processes, interface definitions, system architecture design, pre-selection of suppliers, and support all the way through to the system’s go-live (SOP).

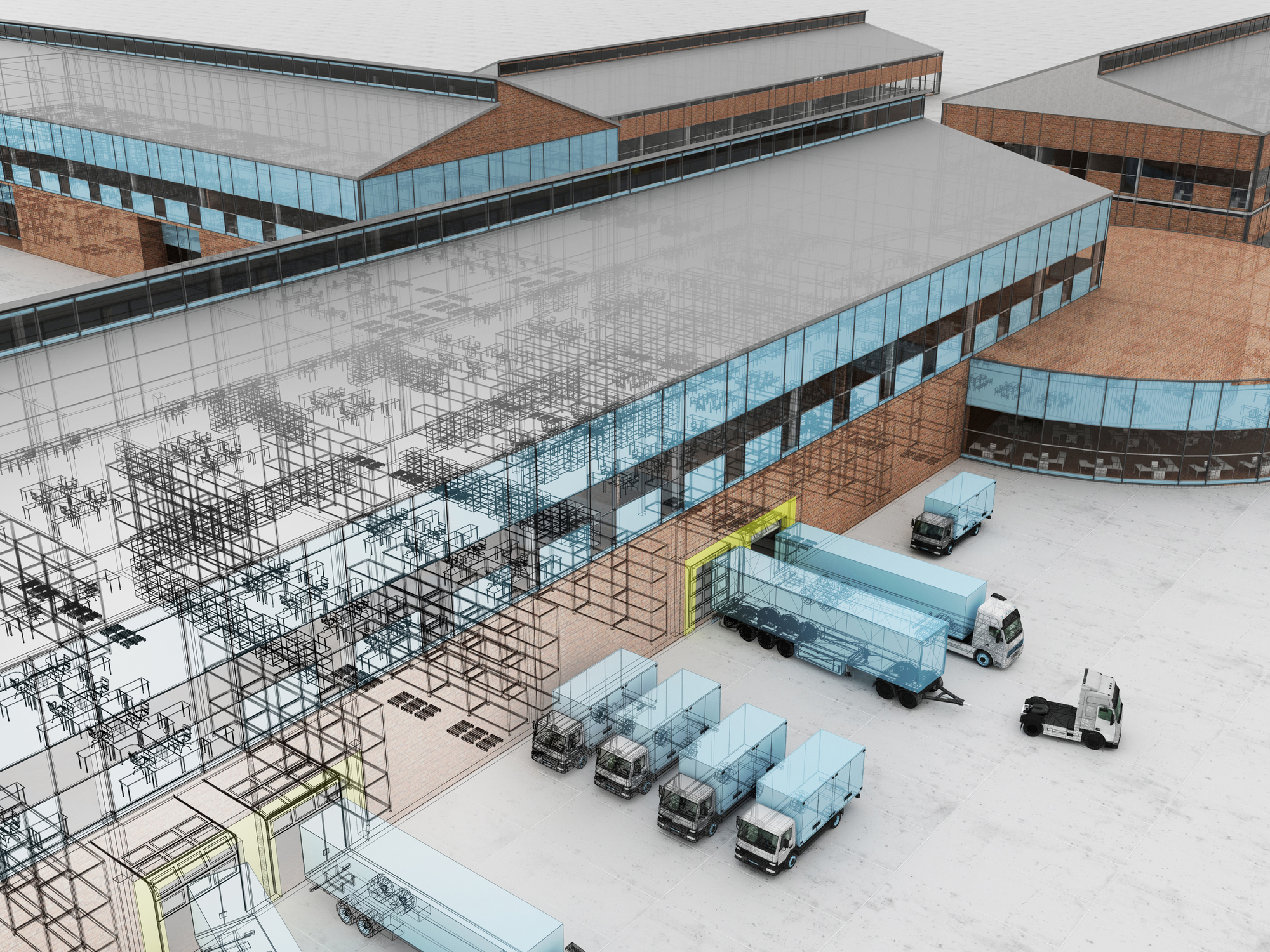

Simulation, Visualization and Animation

We support the analysis and planning of complex logistics processes to enable data-driven decision-making and create transparency around costs, material flows, inventory levels, and system performance.

Today’s companies face increasing complexity, growing product variety, and lower production volumes. To ensure that logistics continues to meet both internal and external demands in the long term, efficient, seamless, and future-proof processes are essential. Our expertise in simulation, visualization, and animation helps analyze complex intralogistics process landscapes and enables databased decisions through planning-based scenarios.

We develop and evaluate solutions using various planning scenarios. This allows potential risks and bottlenecks to be identified early—well before implementation. By modeling intralogistics processes, we help you make well-informed decisions and develop an optimized logistics strategy. Our detailed analyses provide clear insights into inventory, material flows, resource utilization, and system performance over the entire planning horizon, ensuring smooth and efficient intralogistics operations.

All results are presented in a visually compelling format, translating complex intralogistics processes into interactive and easily understandable visualizations. This enables both staff and decision-makers to clearly grasp and evaluate the planned processes.

Our Approach

- Collaborative engagement to capture client needs and objective

- Careful data collection and analysis to ensure model accuracy

- Iterative development and testing of simulation models

- Thorough interpretation and communication of simulation results to support decision-making

- Ongoing support and continuous improvement to ensure model effectiveness