I 4.0 & Digitalization Industry 4.0 – digital, automated, individual

Stable processes, reliable data, sensibly networked.

Reduce costs, increase productivity

T&O accompanies you on the way to the digital factory. Through the close interlinking of shop floor and corporate decisions, we optimize your value chain with the help of our I4.0 core services and thus increase productivity.

Definition and significance of Industry 4.0

Stable and reproducible processes form the basis of any meaningful digitalization. Digital data is useless if it does not reflect reality. With our proven I4.0 core services, we offer you the most stable processes, the most efficient value creation, and the perfect foundation for value-enhancing digitalization.

New Manufacturing Technologies

T&O develops a customer-specific concept for the implementation of new manufacturing technologies, aiming to realize cost savings and value potentials across the entire product lifecycle—in the areas of product design, production planning and engineering, manufacturing execution, and services.

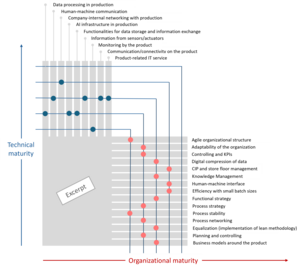

The Industry 4.0 Readiness Check developed by T&O integrates decades of experience in the fields of Lean and Agile Management as well as the specific criteria of Industry 4.0 into an easily manageable audit structure. As a result, you receive a comprehensive and meaningful evaluation of the respective company or organizational unit. The check deliberately differentiates between technical and organizational criteria with the aim of demonstrating that the technical maturity of a company is not effective without corresponding organizational maturity. The same applies, of course – at least with regard to Industry 4.0 – in the other direction as well. The T&O Readiness Check is designed to first capture the status quo of the respective company or organizational unit in a differentiated manner, and then compare it in the second step with an industry benchmark. In the third step, a – certainly debatable vision – of future requirements is outlined to be prepared for the demands of Industry 4.0.

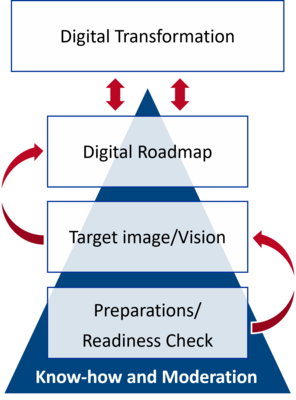

Our core service "Vision and Target Image" supports your company in creating a company-specific Industry 4.0 vision and its target image.

With our structured approach, we moderate and develop the process together with you. We present megatrends and derive market opportunities from them.

Many technologies for Industry 4.0 solution approaches are already available today. However, the benefits of Industry 4.0 only unfold through the skillful linking of these technologies.

The Industry 4.0 vision must become reality. Therefore, we work in interdisciplinary teams, preparing your entire team for digital transformation. Taking into account strategic framework conditions and a risk assessment, a roadmap with short- and medium-term measures is created.

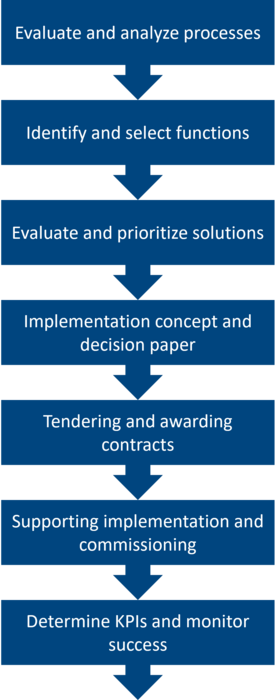

T&O follows a structured path to install targeted robotics and automation solutions in productive and logistical functional areas in seven steps.

In the first step, the processes are analyzed and evaluated regarding cost and quality potentials to identify the processes to be automated.

The second step deals with the selection of potential robotics and automation solutions, based on previously agreed criteria such as: product quality, process stability, ergonomics, …

In the third step, the previously developed solutions are weighted and evaluated according to jointly created evaluation criteria. The goal of the third step is to identify a preferred robotics and automation solution for each relevant process step.

A implementation concept with decision templates is created in the fourth step, for which a deeper data analysis regarding times, costs, investments, and resources is conducted. Resulting from the data analysis, an implementation roadmap is defined and subsequently evaluated in a cost-benefit analysis.

The contents of the fifth step are: defining and specifying robot functions, reviewing and comparing offers, and awarding contracts. For this purpose, a requirements specification is created, the tender is coordinated and accompanied, and the offers are evaluated.

During the implementation and realization, the sixth step focuses on supporting the commissioning and ramp-up phase. This includes project management, implementation support, and acceptance of SOP readiness.

Step seven involves the recording, visualization, and communication of performance data, as well as evaluating the project. In this step, the transfer of KPIs to shop floor management and the implementation of a continuous improvement process are also addressed.

T&O uses a six-phase model for the introduction of new manufacturing technologies in your company. This covers the areas of technical implementation, organizational fine concept, organizational implementation, and project controlling.

As part of the current state check, which includes capturing the framework conditions, a value stream analysis combined with the analysis of material usage, as well as a process check to determine the potential of the currently used technologies regarding their I4.0 suitability, T&O uses not only standard tools but also individual tools such as the T&O Benchmark Catalog.

Building on the current state check, the business case is established. This provides the assessment of feasibility and profitability, as well as the definition of possible potentials. Based on a decision template, the decision for or against the introduction of new manufacturing technologies is made.

Framework conditions regarding implementation (requirements for space, buildings, employee qualifications, etc.) as well as the establishment of a roadmap and conducting the functional tendering based on the specifications follow in the conceptualization phase.

In the fourth phase, the approach for procurement support and preparation for implementation, the best variant is selected based on the evaluation of the tender and a profitability calculation. Following this, detailed project planning takes place.

In the penultimate step of implementation and realization, T&O accompanies you during the commissioning and ramp-up phase of the new systems and supports the adjustment and fine-tuning of process parameters, from which quick wins can be derived.

At the project completion, a cost-benefit analysis will be conducted to confirm the economic viability of the new technologies, as well as a potential analysis to highlight further medium- and long-term realizable potentials. The final step consists of defining the further course of action and the ongoing collaboration.

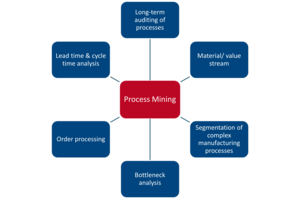

Due to the advancing digital transformation, increasingly larger digital data volumes are being generated. High transparency in business processes is important to discover further optimization potentials and remain competitive.

However, it is not easy to keep track of all these large data volumes (Big Data) and regularly check for compliance. Therefore, it is worthwhile to rely on Data & Process Mining together with T&O.

This method makes it possible to visualize all processes that actually take place, including all exceptions. This achieves 100% transparency in the process overview. It no longer needs to be created manually, and data analysis becomes more efficient. Another significant advantage is the long-term auditing and compliance checking of processes. In short cycles, one can use Process Mining to check how well process standards are being adhered to. This is represented by automated generated and standardized key figures and supports quality monitoring.

More concrete T&O application examples and areas where Process Mining serves for deeper and more accurate data analysis and ultimately for deriving suitable optimization measures include: material flow & value stream analysis, bottleneck analysis, segmentation of complex manufacturing processes, lead time & cycle time analysis, order processing process, and long-term auditing of processes.

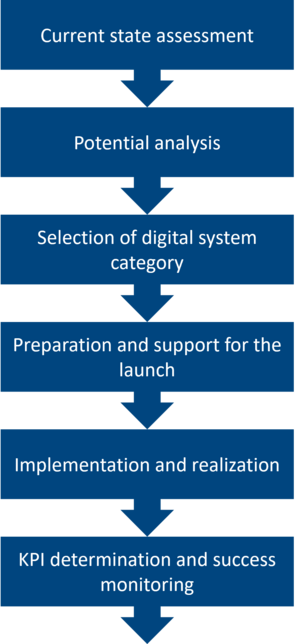

The customer-specific digitalization of the factory at T&O takes place in six successive phases, which cover the entire digitalization process from the current analysis to implementation and optimization. The focus is on both the information flows within production and the information flows within the entire order processing.

Essential prerequisites for digitalization represent an optimized value creation system using Lean methods for all phases, as well as intensive collaboration with all relevant departments.

In the first phase, the current state check, the development of a current IT landscape map takes place, which shows the software systems and communication tools used within the company and their interconnections. The methodological basis for this consists of a value stream analysis 4.0, which focuses on information flows, as well as the collection of relevant key figures.

In the second phase, the potential analysis, an analysis of the current IT landscape map regarding digital waste (Muda) is conducted. Based on this, the greatest optimization needs are identified, so that subsequently the determination of information flows with the most extensive optimization potentials can take place.

In the third phase, a requirements catalog is derived based on a developed target IT landscape map, on the basis of which effective digital system categories are selected.

Based on the creation of a requirements specification, phase four involves the execution of the tendering process, as well as the subsequent selection and procurement of the specific digitalization solution. The detail planning for the subsequent implementation concludes this phase.

In the fifth phase, implementation and realization, the focus is on supporting the commissioning and ramp-up phase. This includes project management, implementation support, and acceptance of functionality.

At the project conclusion in the sixth phase, the relevant KPIs for verifying optimization are determined, and fine-tuning in the form of continuous improvement processes (KVP) is carried out. The project is finally concluded with proof of the project goals to be achieved.