We automate processes, supervise organizational change and gain the acceptance of your employees. To do this, we use big data, introduce new technologies and modern control concepts.

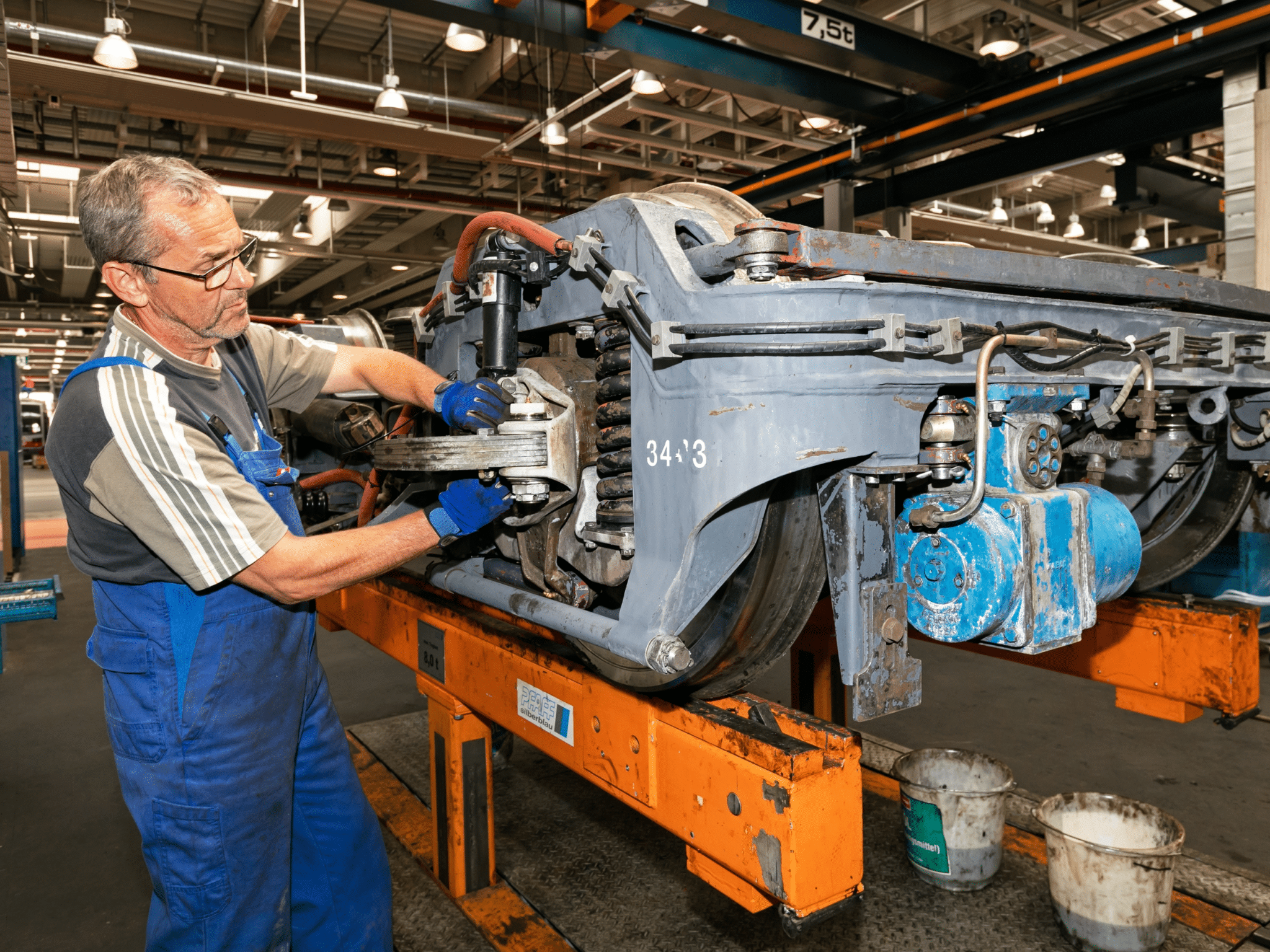

We analyze your maintenance processes to identify opportunities for efficiency improvements. Using our specialized “Shift Accompaniment” method, developed specifically for vehicle maintenance, we document your processes, identify waste, and uncover potential enhancements. Lean and agile methodologies support us in this effort.

Utilizing our extensive industry knowledge and deep understanding of maintenance processes, we derive optimization strategies and define maintenance workflows and concepts.

We analyze your maintenance processes, including content and station allocations, to harmonize and optimize these processes in terms of workflow and execution. By defining and timing maintenance procedures, we help increase your efficiency.

Our goal is to develop efficient workshop concepts that are both lean and agile.

We work with you to develop efficient organizational structures tailored to your needs. We design customized shift models and use our dimensioning tool to accurately simulate the impact of different shift models on station utilization.

With our experience in integrated change management, we also support you in implementing the new shift model effectively.