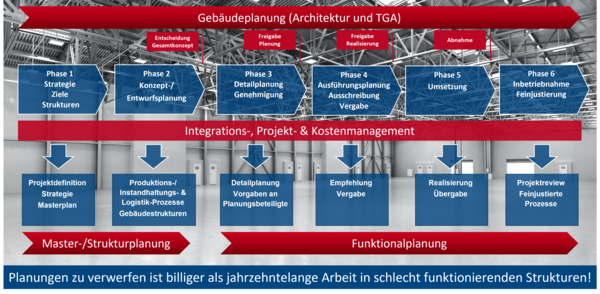

T&O Industrial Excellence offers master planning based on the T&O planning methodology.

This approach differs from conventional factory planning by starting with an ideal model, from which a practical concept is developed.

As a result, it achieves higher outcome quality and significant time savings. This streamlined process leads to increased value creation and improved space productivity.

The path to an "agile and flexible factory"

Our team in factory planning and value creation optimization captures requirements, evaluates them, and translates them into functional and adaptable building structures.

The results from consistent implementation are…

- …significant productivity gains through optimization of material flow and communication

- …minimal investment due to systematic planning

- …high utilization flexibility based on modular structures

- …functionally oriented building structures leveraging extensive consulting experience

- …cost and schedule reliability through pragmatic project and implementation management

We implement and, if required, take responsibility for the project and its outcomes.

- Digitalization of your workflows (from selection, design and optimization to training)

- Automation of your production lines (from value stream, engineering and production support to SOP)

- Digital linking of all production factors (with our tools T/Omorrow Connect, ShopfloorExpress, Kinexxon etc.)

With our subsidiary T&O Smart Factory, we demonstrate the TOP implementation of various digitalization tools along the value chain.